This method only applies to the JDM rubber-gasket windscreen. Some L300s (the Mitsubishi Vans sold in the USA, and some Euro models) have bonded-in windscreens with stainless trim on the outside.

The windscreen glass is the same for all third generation (introduced 1987) L300s. Delicas, delivery vans, US market Van/Wagons, all same. If you're having trouble locating a windshield, tell the autoglass people you have a 1989 Mitsubishi Van, VIN JA4FN44W2KA003233

If that doesn't work, the Pilkington part number is Pilkington Classic (the classic is important) Tri Val FW00563 BBNTRI

Alternative generic part number FW00563BBNPPG (blue tint, blue shade band).

You will need:

Rags

Turpentine or wax and grease remover.

Plastic spudger (spatula/scraper/wedge: a strong non-metal tool you can jam between the rubber and the steel frame)

Masking tape (wide tape makes it easier)

Woven nylon string, shoelace size, about 6 metres.

A caulking gun

Sealant

Maybe a new windscreen seal, if yours is old and hardened.

An Assistant to help with installation.

Paint and rust repair materials (probably).

Part numbers:

Replacement rubber windscreen seal: MB416390 (optional)

3M Sealant 08509 (2 tubes recommended).

Removing the windscreen:

Ideally you'll remove the roof lining (if JDM one-piece molded lining) and A-pillar trims first, but you might get away with slightly lowering the roof lining (remove pillar and door trims, rear view mirror, sunvisors, and plastic clips). The dashboard can stay in place.

Use a plastic spudger tool so it won't scrape the paint (leading to rust later), and when you slip (and you will) it won't break the glass.

It's easiest to start on one side in the middle. Using your spudger, lift the rubber up and tuck it under the windscreen aperture flange. You only need to do the sides and top, the bottom will take care of itself.

Be especially careful when you get to the corners, and don't push on the glass to "help" it. Even if your windscreen is broken, you don't want to break it more than necessary because cleaning glass chips out of the rubber seal is a pain in the ass.

Once you have the top and A-pillars free, the glass should tilt outwards and lift off the lower lip. Easy!

Clean the glass, body aperture, and seal.

The rubber seal should be spotless- any dirt in the seal will grind away at the aperture paint, promoting rust. Dirt in the glass groove can wick moisture into the cabin.

Inspect the glass groove thoroughly. Any glass chips, even small ones, can chip the edge of the new windscreen and start a crack.

Hot soapy water and a scrubbing brush will do most of the cleanup work, turpentine and rags is good for removing traces of old sealant. Clean up the body aperture as well, and fix any rust you find.

Rust/paint repair: I strongly recommend welding up any holes rather than bridging them with polyester filler (Bondo/bog/poo). The windscreen rubber moves about while putting constant pressure on the aperture surface, if you try to bridge holes the filler will eventually detach, cracking the paint at the edge, and letting water in. Filler over the top of metal to smooth out rust pits is ok, but I prefer to epoxy prime the steel before applying the filler- it's just one more layer of protection. For paint repair I use a 2-pack epoxy primer on any bare steel, followed by a 2-pack urethane automotive paint, and left to cure for at least a couple of days. You can brush these on if you use a soft-bristled brush and apply a couple of even coats.

Now is a good time to clean up or replace the screws that hold the front corner panels in.

Replacing the windscreen:

If you have a new windscreen, clean both sides thoroughly with wax and grease remover (or turpentine, then clean rags, then soapy water). They come from the factory with a faint waxy finish which is a bitch to remove once the glass is installed.

Put the rubber seal on the glass first, making sure it's totally square and the corners are all aligned, and then apply masking tape on the outside to hold it to the glass. The tape will stop the rubber from moving on the glass when you're installing it. If the rubber moves out of square, it'll leak.

You'll be installing it using a piece of strong string- a soft woven nylon string, shoelace thickness, is perfect.

Place the string in the seal's aperture groove (where the metal windscreen aperture will end up).

The middle of the string should be about where the rear view mirror will be, run the string around the seal to the bottom edge, cross the string over, and tape the ends to the inside of the glass.

Place the windscreen in the aperture.

With your calm, sensible assistant outside, pushing the glass steadily inwards and down, begin pulling the strings out to flip the seal's lip over the flange. Hold the strings tight, and work them in a circular motion to pull about an inch of rubber over the flange at a time. Your assistant should apply steady pressure through the palms of their hands, keeping the glass in the aperture but also trying to settle the rubber down over the flange.

Don't let go of one end of the string while pulling on the other, you'll just pull the whole string out of the groove and have to start again.

Don't start at one end and go around the windscreen- you'll twist the rubber and the corners won't line up when you finish. Work from the middle outwards, alternating left and right, until you reach the lower corners, then work up the pillars, alternating left and right sides and remembering to secure whichever end of the string you're not currently working with.. Don't let your assistant get excited and start pushing on any one spot to "help" the seal- you'll end up breaking the glass. Just go gently and evenly. If the seal lip gets stuck, go work on the other side for a while. The windscreen will gradually centre itself, freeing up the stuck side. As a last resort you can apply soapy water to the inside lip of the seal to help lubricate it over the flange, but this gets messy.

The top corners are where it's easy to get excited and break the glass. Your assistant should still be pushing the glass inwards and down, but should be doing so as gently and evenly as possible. The rubber seal must pull the glass into the aperture, you should not be pushing on the glass to force the rubber seal home.

Don't thump on the glass to try and encourage it to settle onto the lower aperture flange- it'll settle once you start working on the top edge.

Once you have the rubber seal in place all the way around, it probably won't be sitting completely flat. From the inside, work the seal so it settles all the way home over the flange. That should pull the rest of the seal into place.

Officially, the windscreen doesn't need additional sealant. This might have been true when the bodyshell was new and the rubber seal soft and supple. It's rarely true now, 30 years later. Even if your windscreen aperture is clean and un-rusty, the abraded surface of the paint will try to wick moisture under the rubber. I strongly recommend using sealant.

You want a non-hardening, butyl based sealant intended for rubber glazing. 3M 08509 sealant is perfect. Buy two tubes; it's cheap, you really want to get it in there, and you don't want to run out halfway through the job. Mask around the rubber seal, just up to the edge of the rubber; you'll be getting sealant everywhere, and being able to just pull the masking tape off makes cleanup a *lot* easier.

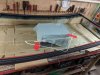

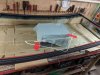

Pump sealant under the rubber seal. It should start to squish back out from under the seal. I didn't take pictures because gross, but here's another car being sealed. There's about the right amount of excess sealant showing, but they forgot the masking tape and now have a horrible cleanup job to look forward to:

Once you've gone all the way around, push on the seal evenly to push as much sealant out as you can. A roller is good for this part. Now use a small square scraper or piece of wood to scrape the excess sealant away from the seal and onto the masking tape. Peel the tape off, and you should be done! If you've managed to get sealant everywhere you can clean up using a rag dampened with turpentine.

The windscreen glass is the same for all third generation (introduced 1987) L300s. Delicas, delivery vans, US market Van/Wagons, all same. If you're having trouble locating a windshield, tell the autoglass people you have a 1989 Mitsubishi Van, VIN JA4FN44W2KA003233

If that doesn't work, the Pilkington part number is Pilkington Classic (the classic is important) Tri Val FW00563 BBNTRI

Alternative generic part number FW00563BBNPPG (blue tint, blue shade band).

You will need:

Rags

Turpentine or wax and grease remover.

Plastic spudger (spatula/scraper/wedge: a strong non-metal tool you can jam between the rubber and the steel frame)

Masking tape (wide tape makes it easier)

Woven nylon string, shoelace size, about 6 metres.

A caulking gun

Sealant

Maybe a new windscreen seal, if yours is old and hardened.

An Assistant to help with installation.

Paint and rust repair materials (probably).

Part numbers:

Replacement rubber windscreen seal: MB416390 (optional)

3M Sealant 08509 (2 tubes recommended).

Removing the windscreen:

Ideally you'll remove the roof lining (if JDM one-piece molded lining) and A-pillar trims first, but you might get away with slightly lowering the roof lining (remove pillar and door trims, rear view mirror, sunvisors, and plastic clips). The dashboard can stay in place.

Use a plastic spudger tool so it won't scrape the paint (leading to rust later), and when you slip (and you will) it won't break the glass.

It's easiest to start on one side in the middle. Using your spudger, lift the rubber up and tuck it under the windscreen aperture flange. You only need to do the sides and top, the bottom will take care of itself.

Be especially careful when you get to the corners, and don't push on the glass to "help" it. Even if your windscreen is broken, you don't want to break it more than necessary because cleaning glass chips out of the rubber seal is a pain in the ass.

Once you have the top and A-pillars free, the glass should tilt outwards and lift off the lower lip. Easy!

Clean the glass, body aperture, and seal.

The rubber seal should be spotless- any dirt in the seal will grind away at the aperture paint, promoting rust. Dirt in the glass groove can wick moisture into the cabin.

Inspect the glass groove thoroughly. Any glass chips, even small ones, can chip the edge of the new windscreen and start a crack.

Hot soapy water and a scrubbing brush will do most of the cleanup work, turpentine and rags is good for removing traces of old sealant. Clean up the body aperture as well, and fix any rust you find.

Rust/paint repair: I strongly recommend welding up any holes rather than bridging them with polyester filler (Bondo/bog/poo). The windscreen rubber moves about while putting constant pressure on the aperture surface, if you try to bridge holes the filler will eventually detach, cracking the paint at the edge, and letting water in. Filler over the top of metal to smooth out rust pits is ok, but I prefer to epoxy prime the steel before applying the filler- it's just one more layer of protection. For paint repair I use a 2-pack epoxy primer on any bare steel, followed by a 2-pack urethane automotive paint, and left to cure for at least a couple of days. You can brush these on if you use a soft-bristled brush and apply a couple of even coats.

Now is a good time to clean up or replace the screws that hold the front corner panels in.

Replacing the windscreen:

If you have a new windscreen, clean both sides thoroughly with wax and grease remover (or turpentine, then clean rags, then soapy water). They come from the factory with a faint waxy finish which is a bitch to remove once the glass is installed.

Put the rubber seal on the glass first, making sure it's totally square and the corners are all aligned, and then apply masking tape on the outside to hold it to the glass. The tape will stop the rubber from moving on the glass when you're installing it. If the rubber moves out of square, it'll leak.

You'll be installing it using a piece of strong string- a soft woven nylon string, shoelace thickness, is perfect.

Place the string in the seal's aperture groove (where the metal windscreen aperture will end up).

The middle of the string should be about where the rear view mirror will be, run the string around the seal to the bottom edge, cross the string over, and tape the ends to the inside of the glass.

Place the windscreen in the aperture.

With your calm, sensible assistant outside, pushing the glass steadily inwards and down, begin pulling the strings out to flip the seal's lip over the flange. Hold the strings tight, and work them in a circular motion to pull about an inch of rubber over the flange at a time. Your assistant should apply steady pressure through the palms of their hands, keeping the glass in the aperture but also trying to settle the rubber down over the flange.

Don't let go of one end of the string while pulling on the other, you'll just pull the whole string out of the groove and have to start again.

Don't start at one end and go around the windscreen- you'll twist the rubber and the corners won't line up when you finish. Work from the middle outwards, alternating left and right, until you reach the lower corners, then work up the pillars, alternating left and right sides and remembering to secure whichever end of the string you're not currently working with.. Don't let your assistant get excited and start pushing on any one spot to "help" the seal- you'll end up breaking the glass. Just go gently and evenly. If the seal lip gets stuck, go work on the other side for a while. The windscreen will gradually centre itself, freeing up the stuck side. As a last resort you can apply soapy water to the inside lip of the seal to help lubricate it over the flange, but this gets messy.

The top corners are where it's easy to get excited and break the glass. Your assistant should still be pushing the glass inwards and down, but should be doing so as gently and evenly as possible. The rubber seal must pull the glass into the aperture, you should not be pushing on the glass to force the rubber seal home.

Don't thump on the glass to try and encourage it to settle onto the lower aperture flange- it'll settle once you start working on the top edge.

Once you have the rubber seal in place all the way around, it probably won't be sitting completely flat. From the inside, work the seal so it settles all the way home over the flange. That should pull the rest of the seal into place.

Officially, the windscreen doesn't need additional sealant. This might have been true when the bodyshell was new and the rubber seal soft and supple. It's rarely true now, 30 years later. Even if your windscreen aperture is clean and un-rusty, the abraded surface of the paint will try to wick moisture under the rubber. I strongly recommend using sealant.

You want a non-hardening, butyl based sealant intended for rubber glazing. 3M 08509 sealant is perfect. Buy two tubes; it's cheap, you really want to get it in there, and you don't want to run out halfway through the job. Mask around the rubber seal, just up to the edge of the rubber; you'll be getting sealant everywhere, and being able to just pull the masking tape off makes cleanup a *lot* easier.

Pump sealant under the rubber seal. It should start to squish back out from under the seal. I didn't take pictures because gross, but here's another car being sealed. There's about the right amount of excess sealant showing, but they forgot the masking tape and now have a horrible cleanup job to look forward to:

Once you've gone all the way around, push on the seal evenly to push as much sealant out as you can. A roller is good for this part. Now use a small square scraper or piece of wood to scrape the excess sealant away from the seal and onto the masking tape. Peel the tape off, and you should be done! If you've managed to get sealant everywhere you can clean up using a rag dampened with turpentine.

Last edited: