CampYerr

Member

Hey Mates, I’ve had a couple of ac issues since purchasing my van last April.

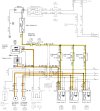

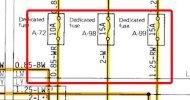

First, I have been having issues with my AC Fuse Link. I replaced my AC link 4 times since last April and trying to figure out why it’s happening so often. Last year DelicaUSA worked on fixing this leak and said it was fixed and also replaced the ac link with an Inline fuse. After a hefty bill, I didn't see anything changed other than the inline fuse and a recharged. Same condenser and compressor, I also never received an itemized bill so there's that. After that, I replaced that with a new ac fuse link from sk66 and did a full cleaning of my battery bay, cleaned each connector, and applied dielectric grease. I do know that the fuse link gets really hot hence eventually burning out. Since this had happened again on my way down to Texas I’m curious to hear what you guys think is causing this. Really don’t want to drive back to NYC without AC and summer is approaching so just want to get everyone’s thoughts before I replace the ac fuse link again.

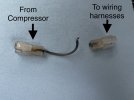

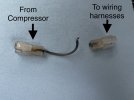

So I’ve noticed a newish 12 gauge wire coming from the compressor. One thing that has been common every time this has happened is that the ac fuse link has always separated from the wiring harness side. Also, both have burned/melted at the spade crimp. I will need to replace the female connector at the wiring harness side as I saw there was a good burn inside the female connector, and the connector as a whole looked burnt out as it felt like it was almost melting into the male connector.

Lastly, my ac has constantly had a small slow leak. DelicaUSA said there was no leak, yet I still have to recharge the AC pretty frequently. I have looked everywhere and can’t find anything with the leak detector. My mechanic also didn’t see a sign of a leak after having the van in his shop for a few days. He also said there was no pressure loss. Yet, my AC eventually goes out.

Please let me know your thoughts and ideas about both issues. Thank you.

First, I have been having issues with my AC Fuse Link. I replaced my AC link 4 times since last April and trying to figure out why it’s happening so often. Last year DelicaUSA worked on fixing this leak and said it was fixed and also replaced the ac link with an Inline fuse. After a hefty bill, I didn't see anything changed other than the inline fuse and a recharged. Same condenser and compressor, I also never received an itemized bill so there's that. After that, I replaced that with a new ac fuse link from sk66 and did a full cleaning of my battery bay, cleaned each connector, and applied dielectric grease. I do know that the fuse link gets really hot hence eventually burning out. Since this had happened again on my way down to Texas I’m curious to hear what you guys think is causing this. Really don’t want to drive back to NYC without AC and summer is approaching so just want to get everyone’s thoughts before I replace the ac fuse link again.

So I’ve noticed a newish 12 gauge wire coming from the compressor. One thing that has been common every time this has happened is that the ac fuse link has always separated from the wiring harness side. Also, both have burned/melted at the spade crimp. I will need to replace the female connector at the wiring harness side as I saw there was a good burn inside the female connector, and the connector as a whole looked burnt out as it felt like it was almost melting into the male connector.

Lastly, my ac has constantly had a small slow leak. DelicaUSA said there was no leak, yet I still have to recharge the AC pretty frequently. I have looked everywhere and can’t find anything with the leak detector. My mechanic also didn’t see a sign of a leak after having the van in his shop for a few days. He also said there was no pressure loss. Yet, my AC eventually goes out.

Please let me know your thoughts and ideas about both issues. Thank you.