Foundmine

Member

So I’m in central Mexico on a 6-7 month “overland” journey and I am having some A/T troubles. The van is a 1996 2.8L diesel LWB, automatic transmission. I am approaching the point of ordering some parts, but I can’t quite figure out what parts I need, or what is even happening to my transmission. I have made one attempt at fixing the issue a few weeks ago, at the recommendation of the mechanics at Nomadic Van, the dealer from whom I bought the Delica. Any help will be greatly appreciated.

The van has reduced power on take off with the transmission in “D”, with O/D on, and the transfer case in 2WD, essentially in normal road driving conditions. The engine revs as normal, and some power gets to the wheels - the van does move, just slowly, until it reaches maybe 20kph, then shifting is essentially normal. Highway driving feels essentially normal, although I am second guessing that. The O/D switch is functioning, the light illuminates on the dash when the O/D is selected, and I can feel a change in the transmission and see a difference in revs. On startup, the A/T light flashes as normal, but when driving the A/T light is not illuminated. There are no other warning lights illuminated on the dash. It feels very much like the van is taking off in 2nd. The “HOLD/PWR” switch seems to be working - the lights illuminate on the dash.

When I shift the van into “L” the problem goes away and there is a normal amount of power at the wheels, and taking off from stopped feels normal. Of course, the van doesn’t shift into 2nd gear when in “L”, but the van does not have reduced power on take off. When I shift into “2” from “L”, the van acts as I believe it should, sometime shifting with a bit of a hard shift if I have over revved a little, but otherwise normal.

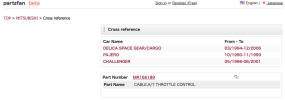

I contacted Nomadic Van, and after a little diagnosing over a sub-par international cell connection, I was advised to inspect and adjust the throttle kick down cable. Upon inspection the measurements looked to be roughly 1-2mm at idle and 34-35mm at wide open throttle, which I believe are in specification. However, at idle the cable had a noticeable amount of slack. I believe the cable should have little slack, or even be under very minor tension at idle. I adjusted the two larger nuts (12mm or 14mm, I can’t recall) to remove the slack. The sleeve moved maybe 10mm, shortening the cable length between the adjustment point and the lever mounted on the injection pump. I didn’t touch the smaller nuts that adjust the lever on the injection pump. I replaced the intercooler and test drove, and everything felt fine - the van had power at takeoff, and the rest of the shifts were fine, maybe a little harder/sharper. I assumed this was because the cable is original and is stretching a little. I treated this fix as a road fix, and I assumed it would drive the same until I could order a new cable.

Yesterday, maybe 1000km after the initial adjustment mentioned above, the issue came back. All the symptoms were the same, with the possible addition of my highway rpms being a little higher than normal (2500ish rpms at 90-100kph) but this may not be an accurate as driving in Mexico is hectic and may have affected my observation. Today, the issue was gone, and the van drove as normal, or at least had power on take off. The highway rpms may still be elevated, but the caveats of difficulty of observation still stand. The primary issue, low power on take off, were gone, with no discernible action from me.

Any advice would be great. Until then, I am holed up at a campground in the central Mexican mountains, eating tacos and drinking coffee and playing fetch with my dog.

The van has reduced power on take off with the transmission in “D”, with O/D on, and the transfer case in 2WD, essentially in normal road driving conditions. The engine revs as normal, and some power gets to the wheels - the van does move, just slowly, until it reaches maybe 20kph, then shifting is essentially normal. Highway driving feels essentially normal, although I am second guessing that. The O/D switch is functioning, the light illuminates on the dash when the O/D is selected, and I can feel a change in the transmission and see a difference in revs. On startup, the A/T light flashes as normal, but when driving the A/T light is not illuminated. There are no other warning lights illuminated on the dash. It feels very much like the van is taking off in 2nd. The “HOLD/PWR” switch seems to be working - the lights illuminate on the dash.

When I shift the van into “L” the problem goes away and there is a normal amount of power at the wheels, and taking off from stopped feels normal. Of course, the van doesn’t shift into 2nd gear when in “L”, but the van does not have reduced power on take off. When I shift into “2” from “L”, the van acts as I believe it should, sometime shifting with a bit of a hard shift if I have over revved a little, but otherwise normal.

I contacted Nomadic Van, and after a little diagnosing over a sub-par international cell connection, I was advised to inspect and adjust the throttle kick down cable. Upon inspection the measurements looked to be roughly 1-2mm at idle and 34-35mm at wide open throttle, which I believe are in specification. However, at idle the cable had a noticeable amount of slack. I believe the cable should have little slack, or even be under very minor tension at idle. I adjusted the two larger nuts (12mm or 14mm, I can’t recall) to remove the slack. The sleeve moved maybe 10mm, shortening the cable length between the adjustment point and the lever mounted on the injection pump. I didn’t touch the smaller nuts that adjust the lever on the injection pump. I replaced the intercooler and test drove, and everything felt fine - the van had power at takeoff, and the rest of the shifts were fine, maybe a little harder/sharper. I assumed this was because the cable is original and is stretching a little. I treated this fix as a road fix, and I assumed it would drive the same until I could order a new cable.

Yesterday, maybe 1000km after the initial adjustment mentioned above, the issue came back. All the symptoms were the same, with the possible addition of my highway rpms being a little higher than normal (2500ish rpms at 90-100kph) but this may not be an accurate as driving in Mexico is hectic and may have affected my observation. Today, the issue was gone, and the van drove as normal, or at least had power on take off. The highway rpms may still be elevated, but the caveats of difficulty of observation still stand. The primary issue, low power on take off, were gone, with no discernible action from me.

Any advice would be great. Until then, I am holed up at a campground in the central Mexican mountains, eating tacos and drinking coffee and playing fetch with my dog.