You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear axle bearing replacement (leaking hubs)

- Thread starter deskinthewoods

- Start date

jixaw

Well-Known Member

it looks like your rear axle seals are seeping....does it smell like nasty gear oil?...if its those seals you are probably ok to drive it till you get it fixed...i know Rising Sun offers the rebuild kits

just be sure its not your wheel cylinder...confirm its not brake fluid

just be sure its not your wheel cylinder...confirm its not brake fluid

deskinthewoods

Well-Known Member

Definitely oil. I’ll check the diff oil level tomorrow before I go anywhere. Helping my daughter move a refrigerator. After that I can park it until I can get to working on it.it looks like your rear axle seals are seeping....does it smell like nasty gear oil?...if its those seals you are probably ok to drive it till you get it fixed...i know Rising Sun offers the rebuild kits

just be sure its not your wheel cylinder...confirm its not brake fluid

There's two oil seals between the diff and the outside world, if both seals have failed that badly then there's likely something a bit more serious going on. I'd jack that wheel off the ground and check for play (vertical as well as in/out.)

deskinthewoods

Well-Known Member

I just checked and there is no play at all, so, YAY! Also checked the oil level in the diff and it is good also. I'll be ordering parts (more parts!!!) and get into that in a while...

So, I figure, both seals, o-ring, bearings (while I'm in there), clips, shims...anything else, or anything not needed?

...just noticed my spelling error/Freudian slip...

So, I figure, both seals, o-ring, bearings (while I'm in there), clips, shims...anything else, or anything not needed?

...just noticed my spelling error/Freudian slip...

Attachments

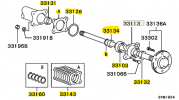

Looks like you have all the right parts selected. 2x Seals, bearing, retainer, O-ring, shim kit. You're using your chassis number, right? Early axles have the bearing retained with a nut, later ones have a pressed-on retainer.

Cutting the retainer off is fairly easy: remove circlip, grind the retainer down, then hit it with a hammer and it will crack. Just don't grind all the way through the retainer and damage the axle.

Once the retainer is off the bearing will still need to be pulled off, and you'll need to make up some kind of puller that bolts to the backplate

You'll need a hydraulic press to install the new bearing retainer, so at that stage it's probably easier to take the axles to a shop. I've installed retainers by freezing the axles and heating the retainer, then pounding it on with a BFH and scaffolding pipe, but a hydraulic press is *way* easier. Also cleaner: you don't want dirt getting in your freshly packed bearings.

I recommend Redline CV2 grease. The rear bearings can't be repacked with grease, so it's worth using the best quality grease you can.

Cutting the retainer off is fairly easy: remove circlip, grind the retainer down, then hit it with a hammer and it will crack. Just don't grind all the way through the retainer and damage the axle.

Once the retainer is off the bearing will still need to be pulled off, and you'll need to make up some kind of puller that bolts to the backplate

You'll need a hydraulic press to install the new bearing retainer, so at that stage it's probably easier to take the axles to a shop. I've installed retainers by freezing the axles and heating the retainer, then pounding it on with a BFH and scaffolding pipe, but a hydraulic press is *way* easier. Also cleaner: you don't want dirt getting in your freshly packed bearings.

I recommend Redline CV2 grease. The rear bearings can't be repacked with grease, so it's worth using the best quality grease you can.

deskinthewoods

Well-Known Member

deskinthewoods

Well-Known Member

Finally getting ready to do this job…Once the retainer is off the bearing will still need to be pulled off, and you'll need to make up some kind of puller that bolts to the backplate

Looking at the photo, will this push the axel down and through the bearing? Will the bearing then need to be pushed out of the backplate? Will it all be self-evident when I get to this stage?

Edit: yes to all those questions.

I’ve built a quick and easy 2 ton shop press. Will this be enough for pressing the bearing/retainer?

Spoiler alert: no.

Attachments

Last edited by a moderator:

deskinthewoods

Well-Known Member

... so... any tips for getting the GD axel out? I've released the brake lines successfully and removed the 4 nuts at the back, attached a 5lb slide hammer and after a good half hour banging away with that it hasn't budged. Canadian winters with road salt and 30 years of age, she's stuck good!

Attachments

deskinthewoods

Well-Known Member

deskinthewoods

Well-Known Member

I’ve fabbed up a puller but nothing is budging (today’s story generally). It seems this is going to push the axle through the back plate/bearing housing, leaving the bearing in the housing, I think.

The retainer is loose on the axel but not loose enough to slide off so my thought was that this pushing the axle out will leave the retainer behind also.

But, tomorrow I’m going to remove the retainer by grinding the other side of it enough to open it up and get it off.

The retainer is loose on the axel but not loose enough to slide off so my thought was that this pushing the axle out will leave the retainer behind also.

But, tomorrow I’m going to remove the retainer by grinding the other side of it enough to open it up and get it off.

Attachments

deskinthewoods

Well-Known Member

deskinthewoods

Well-Known Member

I missed all your replies somehow. Excellent work though! Just for future readers I'll leave my reply here though.

Put the nuts back on the studs until they're flush with the top of the studs (to protect the threads) and hit the studs with a heavy steel hammer. That should pop the backplate free. If that doesn't work, apply a steel wedge (cold chisel?) to the flange in this area, and make sure you file it flat again before reassembling:

(The backplate is glued in place by the silicone sealant on the shims, which presents a large surface area. You need a large, sharp force to break this seal, but the slide hammer is working through the bearing which deforms a little and absorbs the impact, softening the force that makes it to the seal).

Whatever you do now, you have to replace that bearing: the slide hammer has ruined it.

The pictured puller removes the entire backplate and bearing assembly from the axle shaft. Once the axle shaft is out of the way the bearing will come out of the backplate easily.I'm pretty sure the bearing was already pulled in that pic, and the pictured puller pushed the shaft through the backplate.

... so... any tips for getting the GD axel out? I've released the brake lines successfully and removed the 4 nuts at the back, attached a 5lb slide hammer and after a good half hour banging away with that it hasn't budged. Canadian winters with road salt and 30 years of age, she's stuck good!

Put the nuts back on the studs until they're flush with the top of the studs (to protect the threads) and hit the studs with a heavy steel hammer. That should pop the backplate free. If that doesn't work, apply a steel wedge (cold chisel?) to the flange in this area, and make sure you file it flat again before reassembling:

(The backplate is glued in place by the silicone sealant on the shims, which presents a large surface area. You need a large, sharp force to break this seal, but the slide hammer is working through the bearing which deforms a little and absorbs the impact, softening the force that makes it to the seal).

Whatever you do now, you have to replace that bearing: the slide hammer has ruined it.

deskinthewoods

Well-Known Member

deskinthewoods

Well-Known Member

My parking brake has been seized for over a year. I got apart and with some heat and penetrating oil it’s now greased up and functional again…

Attachments

deskinthewoods

Well-Known Member

Note: when fabbing a press, measure your parts first. Had to notch the back plate a tad to fit. It’s mostly rust at this point anyway…

I ground the old outer bearing case down a bit to use to press in the new one. So far a 2 ton bottle Jack is doing the job ok.

I ground the old outer bearing case down a bit to use to press in the new one. So far a 2 ton bottle Jack is doing the job ok.

Attachments

deskinthewoods

Well-Known Member

deskinthewoods

Well-Known Member

deskinthewoods

Well-Known Member

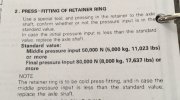

2 tons ain’t gonna do it … but Canadian Tire has a 12 ton Jack on sale for $41.99!View attachment 17626

Hmmmm…

Does this mean I’ll need a press capable of 17,637lbs to install the retainer?!!! Feck!

…I guess I’ll find out…

(I’ll be so bummed if I have to go to an actual mechanic…

When I bought this beast I made a pact with myself to try to do everything myself