Alternator belts that squeal for a while after startup (especially when it's cold) are usually just a bit loose. The glow plugs take a lot out of the battery, so the alternator tries to recharge the battery quickly, putting extra load on the drive belts and making them squeal. Belts that squeal for longer might indicate that the belts are worn or contaminated (oil, mud, road spray with salt or diesel, etc.)

How to tighten the alternator belts (cross posted from Delica.ca)

Steps 1-2 are optional, but advised if this is your first time. Once you've got the hang of it you'll find you can loosen the clamp bolt (2) from underneath.

1) lift up the passenger seat

2) remove the fan cowling (both halves)

3) jack up the front right corner of the vehicle. It is not necessary to raise the wheel off the ground. Lifting the body just gives you a little more elbow room.

4) remove the brush protection pan underneath the engine (2x 14mm bolts and 4x 12mm bolts)

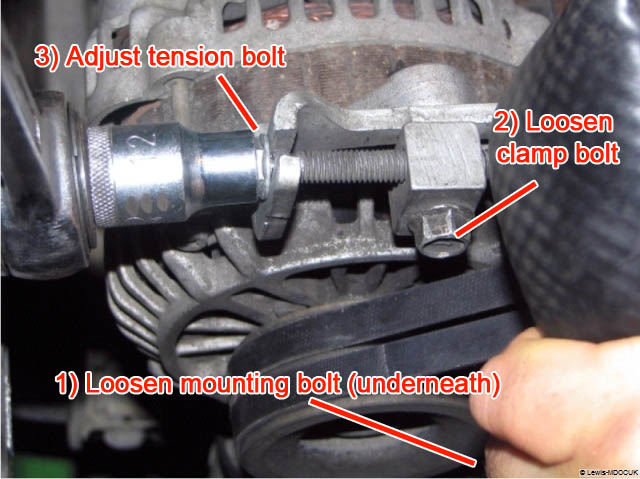

5) loosen the alternator mounting bolt from underneath (1) the vehicle using a 12mm socket and wrench

6) loosen the clamp bolt (2) that locks the alternator in position. From above is easier (after you've removed the fan cowling) but from below is possible.

Here's an impossibly good view of what you're trying to adjust. You'll never see this, you'll be doing it all by feel:

7) Use a ratcheting box wrench on the tension bolt (3), or alternatively remove the driver's side front wheel, lift the rubber flap in the wheel well, and if you're lucky the tension bolt head (3) will be reachable using a socket and long extension. You may need a universal joint on the socket.

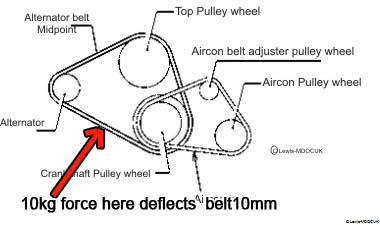

8) A correctly tensioned alternator belt will deflect 10mm when pushed with a force of 10kg/22lb, pressed in the middle of the lowest run. If you press with your thumb about as hard as you comfortably can, that's around 10kg. If you're unsure, use a bathroom scale to calibrate your thumb.

9) go back out the way you came in, tightening everything you loosened, and putting back everything you took off.

If the belts continue to squeak when correctly tensioned you'll need to replace the belts. Don't overtighten them in an effort to stop the squeaking- the water pump bearing will fail. Trust me, I know.

How to tighten the alternator belts (cross posted from Delica.ca)

Steps 1-2 are optional, but advised if this is your first time. Once you've got the hang of it you'll find you can loosen the clamp bolt (2) from underneath.

1) lift up the passenger seat

2) remove the fan cowling (both halves)

3) jack up the front right corner of the vehicle. It is not necessary to raise the wheel off the ground. Lifting the body just gives you a little more elbow room.

4) remove the brush protection pan underneath the engine (2x 14mm bolts and 4x 12mm bolts)

5) loosen the alternator mounting bolt from underneath (1) the vehicle using a 12mm socket and wrench

6) loosen the clamp bolt (2) that locks the alternator in position. From above is easier (after you've removed the fan cowling) but from below is possible.

Here's an impossibly good view of what you're trying to adjust. You'll never see this, you'll be doing it all by feel:

7) Use a ratcheting box wrench on the tension bolt (3), or alternatively remove the driver's side front wheel, lift the rubber flap in the wheel well, and if you're lucky the tension bolt head (3) will be reachable using a socket and long extension. You may need a universal joint on the socket.

8) A correctly tensioned alternator belt will deflect 10mm when pushed with a force of 10kg/22lb, pressed in the middle of the lowest run. If you press with your thumb about as hard as you comfortably can, that's around 10kg. If you're unsure, use a bathroom scale to calibrate your thumb.

9) go back out the way you came in, tightening everything you loosened, and putting back everything you took off.

If the belts continue to squeak when correctly tensioned you'll need to replace the belts. Don't overtighten them in an effort to stop the squeaking- the water pump bearing will fail. Trust me, I know.

Last edited: