Nulla

Active Member

I got the OEM injectors. For sure I will not use this shop again. They been in business for 73 years rebuilding IP and injectors that is why I picked them. I asked to tune my IP a bit higher to get better performance. Should I take my new injector to the shop so that they can tune the IP to the new injectors? Is this necessary?What @Scott said. Bosch/Zexel injectors are designed to be rebuildable. If the shop doesn't want/know how to rebuild them, they're just lazy or incompetent.

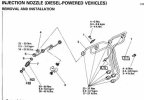

Rebuilding (replacing the nozzle and pintle) is a safer option than replacing, as you keep your OEM quality injector bodies and springs which are guaranteed to work with your injection pump. Rebuilding also means recalibrating, which ensures all four injectors are working the same. That's not something guaranteed with cheap replacements.