f1del

New Member

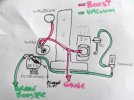

hi , i have a D4DF and im not sure about my vacuum lines, my turbo doesnt seem to be boosting and the wastegate isnt opening, but one doubt remains, which vacuum line goes to the top of the fuel pump ? is that the boost compensator?

- i swapped from a D4BH to a D4BF which i got around 6 months ago, i have a boost gauge waiting to be installed, and im going to buy a manual boost controller and the plug for the boost relief valve, but im still unsure if my vacuum lines are connected correctly , and it definitely isnt opening up the wastegate as i had it straight piped for a while with both engines and the d4bh made alot more lovely spooling and wastegate "dumping" noises

i was running it without the vacuum pipe to the fuel pump for a bit but someone pointed it out and i connected it up , there was a small increase in power or throttle response but theres definitely lacking spooly noises - could the old washer on the wastegate bolts do the trick ? or is it even necessary to do that if i get the manual boost controller installed?

Cheers everyone !

- i swapped from a D4BH to a D4BF which i got around 6 months ago, i have a boost gauge waiting to be installed, and im going to buy a manual boost controller and the plug for the boost relief valve, but im still unsure if my vacuum lines are connected correctly , and it definitely isnt opening up the wastegate as i had it straight piped for a while with both engines and the d4bh made alot more lovely spooling and wastegate "dumping" noises

i was running it without the vacuum pipe to the fuel pump for a bit but someone pointed it out and i connected it up , there was a small increase in power or throttle response but theres definitely lacking spooly noises - could the old washer on the wastegate bolts do the trick ? or is it even necessary to do that if i get the manual boost controller installed?

Cheers everyone !